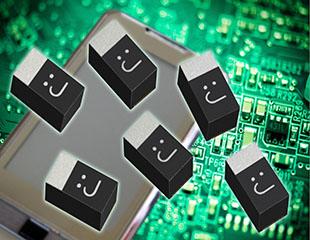

Ready for harsh automotive conditions: Compact surface-mounted Power Choke Coil

With the new ETQPAMR33JFW of renowned Power Choke Coils, Panasonic now commercializes compact surface-mounted inductors capable of passing large currents

For quite a while now, “the electrification of everything” is one of the major trends in automotive engineering: More and more electronic devices, electric motors, inverter systems and ECUs are to be integrated in cars. So, mounting space is precious, but the requirement to handle high currents is essential as never before.

Conventional through hole mounting (THD) types of inductors are way too large to contribute to a significant overall downsizing, let alone the clear trend of all modern components being ready for surface-mounting.

Considering all this, Panasonic Industry now introduced its latest automotive power inductor: Being only half the size of a conventional ferrite type, this new SMD Power Choke Coil is ready for high currents under harsh automotive conditions. It can be operated under temperatures up to 160℃ including self heating – and even shows stable behaviour at several hours up to 180℃. Its low loss characteristics ensure a high ECU efficiency and contribute to simplify the overall thermal design process.

The metal composite material clearly outperforms the ferrite technology: The coil heat generation is reduced while the coil heat dissipation is increased. A large current of 83A rated and 103A saturation current are achieved while significantly reducing the coil’s volume.

Given all this, the inductor enables ECUs to be directly mounted on engines by ensuring not only an excellent heat resistance, but also an outstanding vibration robustness, namely 5 Hz to 2 kHz / 30G due to its unique integral structure by direct leading wire and caulking structure with a core body.

Applications

- Powertrain

- brake or steering circuitry noise filters

- boost converters

- buck converters or ADAS systems

Datasheet

Link to Rutronik24