OSRAM – Vertical take-off for VCSEL technology in IR applications

Imagine being able to do a 3D scan of your foot with your smartphone and send the image to a manufacturer who then adapts a shoe perfectly to your foot. These and other ideas could soon become reality – with a technology called VCSEL.

What does VCSEL mean? How does it work?

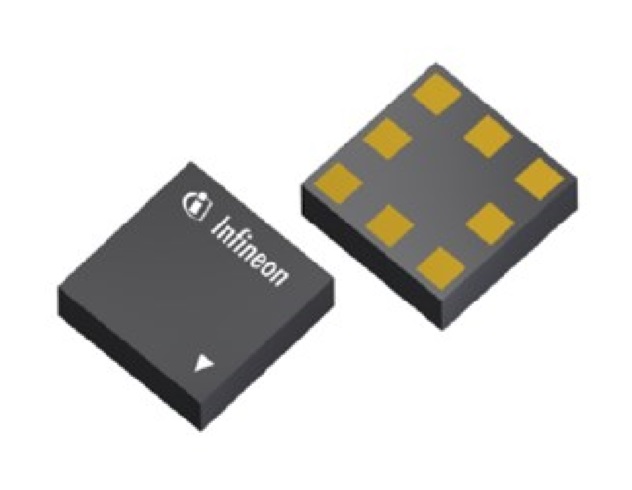

VCSEL stands for vertical-cavity surface-emitting laser – this is a laser diode with a monolithic laser resonator which radiates the light vertically to the surface of the semiconductor chip, as opposed to edge-emitting laser diodes, where the light exits at the edge of the chip.

The technology can also be used as a VCSEL array – a composite of several hundreds of VCSELs – glued and bonded like a normal LED.

What are the advantages and disadvantages?

Decisive features of the surface emitter lasers (compared to edge emitting lasers) are the lower production costs and the better beam quality – however with a lower output power. The coupling efficiency in optical fibers is high due to the small footprint, the good beam quality and the good focusability.

As an SMT (surface-mountable component), a VCSEL combines characteristics of an LED with those of a laser and is easier to assemble than an EEL (edge emitting laser).

It offers coherent light with directed emission, the higher power density and simple packaging of an IRED, but has the spectral width of a line emitter, like EEL or DFB (distributed feedback laser diodes) technology.

The beam shape of a VCSEL is a circular spot, compared to the elliptical shape of FP-EEL (Fabry-Perot Edge Emitting Laser) and DFB. Unlike the temperature sensitive wavelength of an EEL, VCSEL suffer way less wavelength shift under the influence temperature changes.

The main advantages of the different IR technologies can be summarized as follows:

- VCSEL: cost effective chip, narrow divergence, high efficiency

- EEL: High performance, very high efficiency, high luminance

- IRED: homogeneity of lighting, very cost effective chip, wide range of different models

In which application areas have VCSELs been used so far?

The application focus for VCSEL technology has been on data communications for the last decade, but recently, a variety of applications have been discovered in various end markets.

Which application areas are evolving today and for the future?

VCSELs are used across a wide range of applications due to their advantages of compact size, low energy demand and high reliability. In general VCSELs are a good choice for all application fields where high-speed modulation is an advantage.

The favorable manufacturing cost ratio and high reliability have led to an increased use of VCSELs in mobile and consumer electronics. There are already first application examples in the consumer mobile device segment. 3D sensing is also being integrated with augmented reality (AR) and virtual reality (VR) – either for smart glasses or future smartphones and other mobile devices.

The rising use of electrical systems in automobiles is another factor fueling the growth of the global VCSEL market. In the automotive sector, the technology is expected to be used for applications such as gesture recognition, driver monitoring or sensors for (semi) autonomous driving.

Additional application fields include robotics, security and surveillance cameras, IR heating or machine vision for industrial applications.

Will VCSEL replace other IR technologies?

Although the VCSEL technology offers many advantages compared to existing IR technologies, it is not automatically a universal solution for all segments but rather an extension of the IR portfolio of OSRAM Opto Semiconductors

Customers now have the choice to compare the technical features of IREDs, edge lasers and VCSEL based technologies to select the best suited solution for their specific application.