Magnetic Sensing in Clothes Dryers

Introduction

Clothes dryers have had a history of being energy inefficient ranked only behind the refrigerators and freezers.

Like many modern appliances, clothes dryer designed with microprocessor based controllers allow the use of a variety of sensors to ensure proper, safe, and energy-efficient operation. Littelfuse’s magnetic sensor products help make these appliances as reliable as ever.

Reed sensors and Hall Effect sensors are both very reliable and will operate over millions of cycles with long-term integrity when used with microprocessor electrical loads. Both reed and Hall Effect devices are operated by a magnetic field. Reed switches and sensors consume no power, while Hall Effect devices are semiconductors and will consume a small amount of current in both the activated and de-activated state.

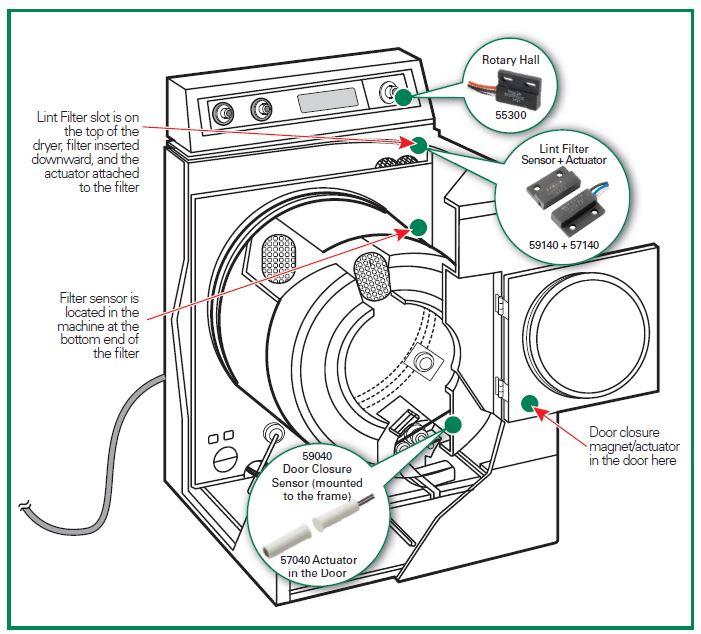

Dryer Door Closure Sensor

The typical dryer in past designs had used a mechanical pushbutton switch as the closure switch. However, these mechanical switches within this warm and humid dryer environment can encounter problems with oxidizing contacts at this low switching voltage. This can cause erratic switching continuity. A reed sensor or Hall Effect sensor will overcome this issue since the reed switch is hermetically sealed and the Hall is an IC.

The dryer door magnetic sensor sends a signal to the microcontroller that the door is closed or open. The non-contacting sensor can either be a reed or Hall Effect digital signal device.

The reed sensor or Hall Effect is fixed on the outer frame while the actuator/magnet would be placed within the dryer door.

Littelfuse recommends the following products as door closure sensors and actuators

Suggested Products

55140 Hall effect Sensor http://www.littelfuse.com/~/media/electronics/datasheets/hall_effect_sensors/littelfuse_hall_effect_sensors_55140_datasheet.pdf.pdf

59040 Reed Sensor

Customized Solutions

Dryer Rotary Selector Switch

Most dryers are equipped with the popular control/selector knob for adjusting the proper drying cycle. If the dryer is equipped with a micro-controller, then a closed-loop temperature control system can be in place for better temperature consistency.

With this controller, a non-contact solution would be preferred for improved long-term reliability. A programmable rotary Hall Effect sensor is ideal for this application with 0.5V to 4.5Vdc output over 360 degrees of rotation.

The rotary Hall Effect device is a semiconductor that responds to a magnetic field. This device detects changes to the angle of the magnetic field or strength of the field as a magnet rotates over the sensor. The change in field during rotation is converted to an analog output voltage, or a pulse-width modulated (PWM) signal. The magnet is placed onto the control knob, while the sensor is placed on the fixed surface directly behind the magnet.

Suggested Products

55300 rotary Hall Effect with mating magnet http://www.littelfuse.com/~/media/electronics/datasheets/hall_effect_sensors/littelfuse_hall_effect_sensors_55300_datasheet.pdf.pdf?utm_source=hamlin.com&utm_medium=redirect&utm_content=datasheet&utm_campaign=hamlin-lf

55250 rotary Hall Effect http://www.littelfuse.com/~/media/electronics/datasheets/hall_effect_sensors/littelfuse_hall_effect_sensors_55250_datasheet.pdf.pdf?utm_source=hamlin.com&utm_medium=redirect&utm_content=datasheet&utm_campaign=hamlin-lf

Customized Solutions

Lint Filter Sensor

Dryers account for one of the leading causes of household fires. Failure to clean the dryer system, including the lint filter is the major cause. A magnetic sensor can be used to detect that the lint filter is fully inserted and in proper position. This can also be part of a closed loop system as a reminder to clean the filter frequently. The filter would contain the magnet/actuator, while the sensor would be located near the filter. The filters are located in different areas of a dryer, possibly on the top, or in the front, or on the bottom, depending on the brand.

Suggested Products

59140 Reed Sensor

59165 over molded surface mount reed

55140 Hall Effect Sensor

Customized Solutions

Drum Speed Sensing

A Hall Effect sensor is a very effective device used for detecting the rotating speed of a dryer drum. Hall Effect sensors offer fine-resolution measurement and are well suited for high-speed applications.

A rotating multi-pole ring magnet, usually containing 16 or 32 north and south poles, is attached to the drum axis, and rotates over top of the Hall effect speed sensor (as shown in Figure 3). The Hall detects the pole change frequency as the magnet rotates and is fed to the microprocessor. The microprocessor then determines if the speed is correct and signals the motor drive accordingly

Suggested Products

55310 Flat pack digital sensor

FEATURES AND BENEFITS OF HALL EFFECT SENSORS

• No physical contact required to operate the sensor

• Wide operating temperature range

• Digital or analog options for output signal

• Programmable on both digital and analog applications for tight output tolerances

• Effective for high-speed applications

• Encapsulated sensors provide additional protection against mechanical stresses

• Long lifetime and reliable sensing for millions of operations

FEATURES AND BENEFITS OF REED SWITCHES

• Switch activation does not require physical contact

• Switch contacts are within a hermetically sealed capsule

• Resistant to moisture, dust, and other foreign objects

• Wide operating temperature range

• Reliable switching

• Long lifetime