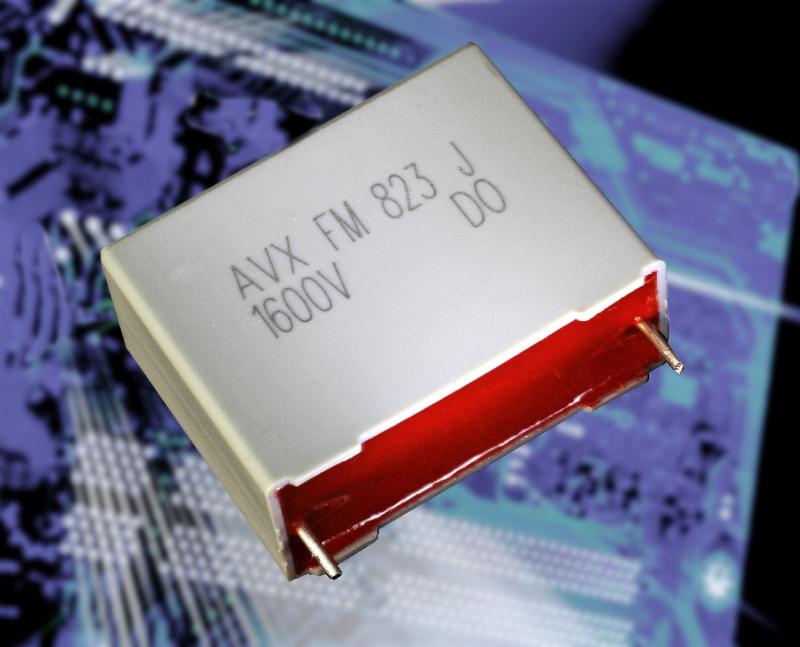

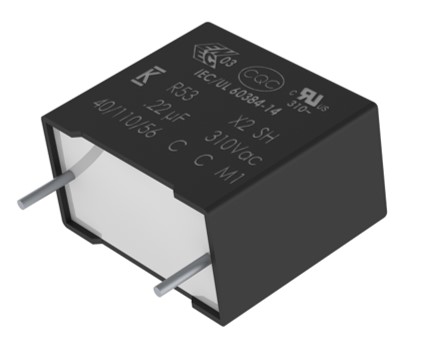

AVX – New Polypropylene Film Capacitors for Power Supply, DC und Pulse Applications

AVX Corporation, a leading manufacturer of passive components and interconnect solutions, has released the new FM Series medium power film capacitors.

Non-inductively wound with dry, metallized polypropylene film dielectric and encapsulated in a flame retardant plastic case sealed with self-extinguishing, thermosetting epoxy resin and featuring RoHS-compliant double metallized polyester film electrodes in series construction, FM Series capacitors exhibit high reliability at high current stress, high dv/dt capability, high moisture resistance, high capacitance stability, low losses, self-healing properties, and long useful lifetimes.

Rated for capacitance values spanning 0.01µF to 0.47µF, voltages spanning 250V to 2000V, and operating temperatures spanning -40°C to +105°C, the new FM Series capacitors are designed for high frequency and high pulse rise-time circuits, high voltage power supplies, switch mode power supplies (SMPS), power converters, snubbers, and electronic lighting ballasts, such as compact florescent lamps and LEDs.

“Principally designed for power supply, DC, and pulse applications, our new polypropylene dielectric FM Series medium power film capacitors exhibit excellent high reliability performance and are available in a wide range of case sizes, voltages, capacitance values, and tolerances, enabling their employment in an extensive range of end products,” said Gilles Terzulli, worldwide marketing manager, power film capacitors, AVX. AVX’s FM Series medium power film capacitors are available in 17 case sizes (A-S), 14 voltages (250-2000V), three capacitance tolerances (±5%, ±10%, and ±20%), and two lead lengths (3.5mm and 22mm).

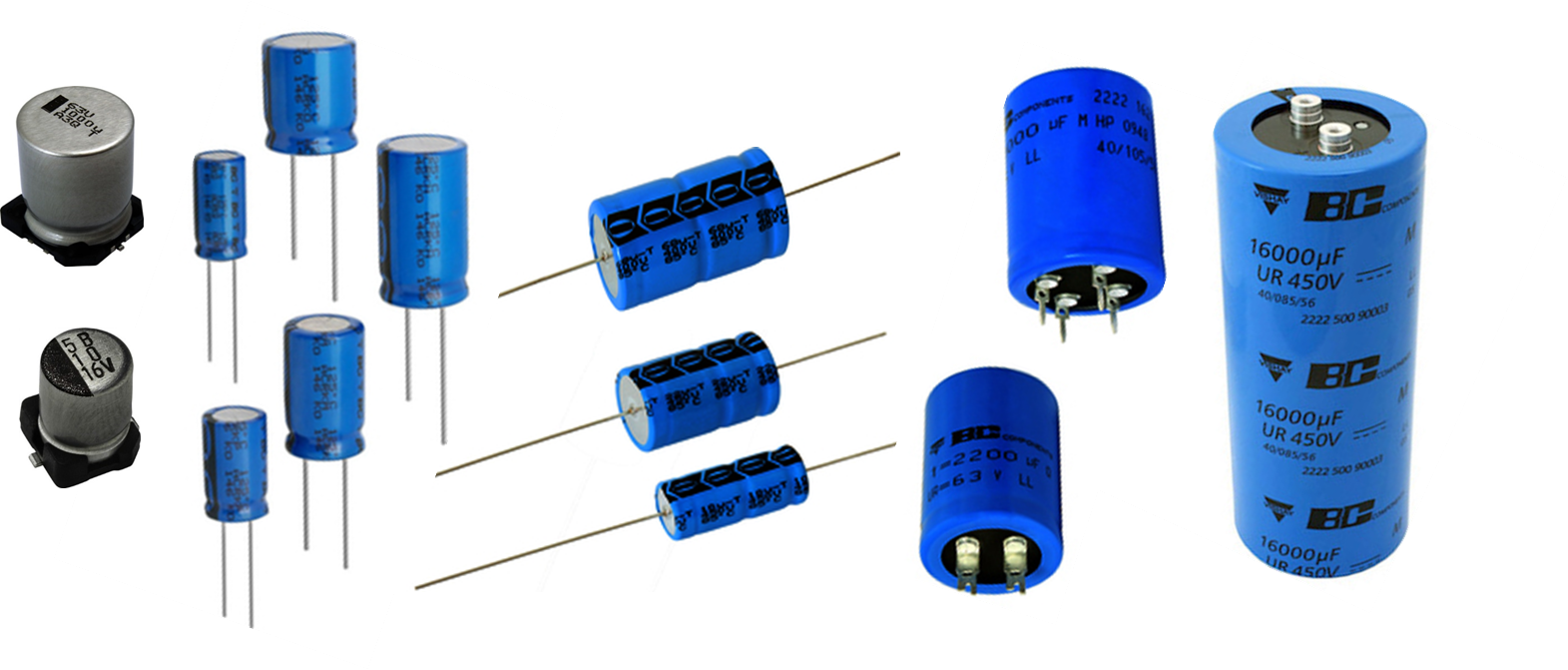

Additionally, unlike aluminum electrolytic capacitors, FM Series film capacitors do not have a catastrophic failure mode. Instead, FM Series capacitors simply experience a parametric loss of capacitance of approximately 2% from their initial value, eliminating the risk of short circuit and enabling continued functionality. Lead time for the series is approximately eight weeks.