Automotive Protective Componets from KEKO-Varicon

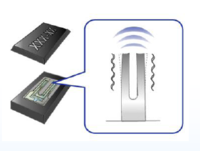

DC motors used in many automotive and other applications generate substantial amount of electromagnetic noise which can interfere with other electronic systems and consequently compromise their functions. According to various regulations the electromagnetic interference (EMI), also called radio-frequency interference (RFI), must be suppressed below alowable limits.

Keko Varicon has received a DC motor without any EMI protective components and was asked to select the most appropriate EMI protection solution for the particular motor.

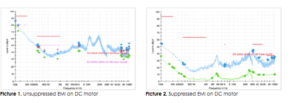

Radiative (RE), conductive (CE) and transient (TE) emissions of the DC motor without EMI protection components were tested. EMI emissions were out of limits and therefore a component that would suppress EMI was needed.

Applications: Anti-block brake system, Airbag control system,

Wiper motors, Central locking system, Seat heating

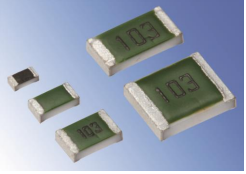

Emission tests were performed on same DC motor again but this time different OV components were used on a brush card of a DC motor. The OV component that suppressed EMI most was selected as an optimal protective component for this particular DC motor.

The emissions of the DC motor with selected OV component were below the allowed limits and DC motor was approved for the use in automotive application.