Molex – MXP120 Sealed Connector System Handles Harsh Environments

Molex Incorporated announces its new MXP120™ Sealed Connector System – a 4.00mm pitch high-performance connection system based on 1.20mm terminals for automotive and commercial vehicle in-line harness applications. Meeting medium power application requirements up to 13.0A, the MXP120 can replace common 1.50mm systems to achieve a smaller, more compact solution. Conversely, the MXP120 offers much more current carrying capacity and robustness than is possible with the smaller 0.64mm terminal systems.

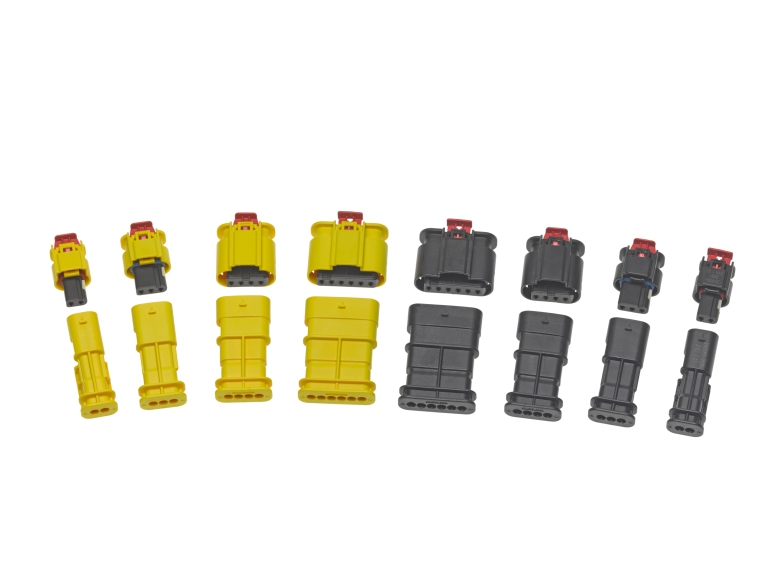

Compatible with AK and USCAR interfaces, the MXP120 is designed according to the worldwide AK cavity definition and therefore conforms to global requirements. Connectors in yellow housings are qualified according to T3-V2-S2 (+125°C / 250 m/s²) performance level for in-vehicle safety system applications.

Black housings with standard USCAR polarisation options will follow. These housings are being validated to meet T4-V4-S3 specifications (per GMW3191) for high-performance (155°C / 300 m/s²) for use in space-constrained powertrain applications.

New applications are also emerging in vehicle body-electronics for compact direct or in-line connections with lower performance requirements (125°C / 30 m/s2). The black connectors will be equally well-suited for many industrial and consumer applications where sealing is required and package size is a constraint. The MXP120 receptacles feature an integral locking-latch that provides excellent mating performance and an audible click upon latching for superior safety. In addition, a bridge over the latch protects it completely from potential damage or permanent stress during packaging and storage and helps ensure latching performance is maintained during service life. The single wire seal (SWS) connection systems with robust perimeter seal can withstand high-pressure spray environments to IPx8 levels.

The MXP120 Sealed Connector System features an enlarged and robust Connector Position Assurance (CPA) clip for superior ergonomics and to reduce the risk of breakage or pre-seating prior to mating. After connector mating, the CPA and the integral latch combine to stabilise the connector interface without impact to the mating force