LIQUID LEVEL SENSING – USING REED SWITCH TECHNOLOGY

COTO CT 10 and Coto CT 05

COTO CT 10 and Coto CT 05

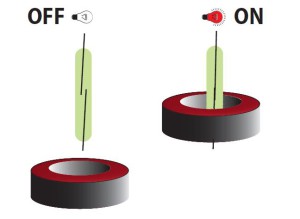

When measuring discrete levels of liquids,

such as automobile brake fluid, reed switch

technology is simple, inexpensive, and

reliable. A magnet mounted on a float closes

an adjacent magnetic reed switch as the

magnet approaches. Typically, the reed switch

is mounted in a plastic or non-magnetic metal

tube, and a ring magnet mounted on a float rides up and down the

tube on the liquid surface (Fig. 1). A ring magnet is a good solution

since as the magnet sweeps by the reed switch, only one closure

occurs as the plane of the magnet lines up with the contact gap of the

switch. Other types of magnets can cause two or even three separate

closures, causing potential problems in the software used to monitor

the level sensor. Also note that if the wires to the sensor are severed,

the system registers low. It is therefore fail-safe.

This method is frequently used in automobiles for monitoring brake

fluid levels. It can be modified to register multiple levels by incorporating

a chain of reed switches. By using three reed switches instead of

one, for example, the reed switch level sensor can register a RED alert –

“stop and check brake fluid immediately,” ORANGE – “check brake fluid level soon,” and GREEN – “brake fluid level OK.”

Discrete voltage levels corresponding to each switch closure can be

developed using a resistor ladder. A typical configuration for a

4-switch system is shown in Figure 2. The resistor network can be

extended to any number of levels depending on the depth of the tank

and the switch separation. Thus deep tanks can be monitored with

many discrete levels. Schemes can also be devised to “tune” the

resistor values to suit tanks with spherical or other varying cross

sections.

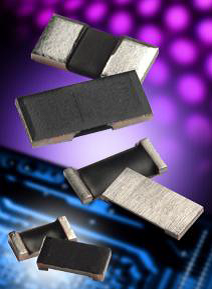

Choice of reed switch

Since bare glass reed switches are fragile, a better choice is a plastic

encapsulated reed switch such as Coto Technology’s CT05 or CT10

series. They consist of a high-quality reed switch encapsulated in a

hard epoxy resin, which effectively “splints” the reed switch, protecting

it from shock, vibration and environmental damage. As such, they

are ideal for under-hood automobile operation. The CT05 series

switches are surface mount devices 6.4 mm long (9.55 mm including

leads), and are also available in a slightly shorter J-bend format. The

CT10 series is 12.8 mm long (16.4 mm with leads).

Apart from the advantages of increased ruggedness, the surface

mount format makes it simple to attach the switches to printed circuit

boards or flex circuits using pick-and-place equipment. While

designing the CT05 or CT10

switches into a sensor, note that every switch that leaves the Coto factory is tested for

operate and release sensitivity AFTER lead cropping and

encapsulation, ensuring that these sensitivities are known

accurately. In contrast, other reed switch manufacturers test the operate and release

sensitivity before lead cropping and molding, and can only

make a rough estimate of the sensitivity of the shipped product.

Relationship between Amp-Turn (AT) operate and release

sensitivity, and required operate and release field

The CT05 and CT10 series reed switches are specified in terms of the

range of operate AT. For example, the CT10-1030-G1 switch has a

range from 10 to 30 AT. In other words, Coto warrants that a switch

randomly selected from a batch of CT10-1030-G1 switches will operate

in a field of between 10 amp-turns and 30 amp-turns measured in

Coto’s factory test coil. (The specification for this coil is available on

request.) However, most CT series switch users expect to use a

permanent magnet to operate the switch. What magnetic field

strength is needed to operate a 10 AT switch? There is a simple rule of

thumb to figure this. It is: 4 AT = 1mT. In other words, divide the

switch AT by 4 to get the required field strength in milliTeslas (mT). So

the 10 AT switch will operate when immersed in a field of approximately

10/4 = 2.5 mT (25 Gauss in the older CGS units.) Correspondingly,

a 30 AT switch will close at 7.5 mT.

For a deeper look into this topic and for additional level sensor design considerations,

please see Coto’s full Application Note AN1602-1 entitled “Liquid Level Sensing Using

Reed Switch Technology”.

–

COTO TECHNOLOGY, INC | www.cotorelay.com | OPPLIQLEV0316®

Data sheet CT 05 / Data sheet CT10 / Application Note Complete Article