Miniaturization of Electrolytic Capacitors

The development of the electrolytic capacitors is progressing steadily, which significantly affects the design and capacity.

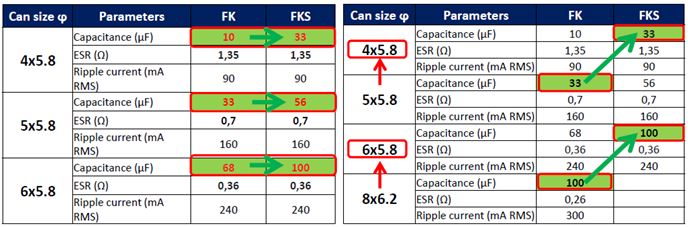

table 1: Size / Capacity – overview of two Panasonic SMD series ( Source: Panasonic )

Especially the Japanese world market leaders concentrate on the technological development as well as the increasing miniaturization.

As an example, there is the progressing optimization of the Aluminium foil or the used electrolyte.

This allows to increase the capacity within the same case size – or e.g. an improvement of the lifetime.

It should also be noted that such a miniaturization does not necessarily mean poorer technical values like ESR and ripple current.

The larger can size which is shown in table 1 is a typical highrunner product, available from different manufacturers. To be always a technology leader

and to cover the market demand related to smaller case sizes, it is essential to make new developments.

All that enables our customers lots of advantages like the reduction of space on the circuit board or a reduced number of components needed.

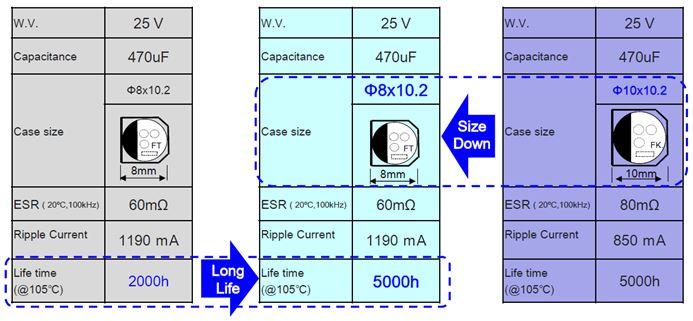

But the improvement of the performance is not only related to the capacitance and case size, furthermore it is also related to the

lifetime. (table 2)

table 2: Size / Lifetime overview of three Panasonic SMD series ( Source: Panasonic )

Gernerally a higher lifetime is related to a larger component, but today it is possible to increase the lifetime within the same case size.

For all these reasons, it makes sense to follow up the new developments also within the Aluminium Electrolytic Capacitors technology, to be able to create the design as efficient as possible. This helps our customers to provide the latest technology with their products and control the costs of their newest product generation.

These are advantages which help them to conquer the challenges of every-changing markets.