Maxwell Technologies Sets a New Standard for Energy, Power and Ruggedness with the Latest Addition to its Market Leading Family of Large Ultracapacitor Cells

Maxwell Technologies also introduces the DuraBlue Shock and Vibration Technology, the newest innovation in ultracapacitor reliability and performance. Products with DuraBlue technology are tested to some of the most demanding environmental requirements for transportation, increasing vibrational resistance by approximately 3 times and shock immunity by 4 times when compared to ultracapacitor-based competitive offerings. Thus, making it the world’s most ruggedized cell.

Franz Fink, Maxwell’s Chief Executive Officer said “This latest addition to our widely popular K2 Series of ultracapacitor cells reflects Maxwell’s commitment to continuous customer-driven innovation, and delivers superior performance with unmatched reliability and value,” Maxwell’s new DuraBlue Advanced Shock and Vibration Technology combines Maxwell’s unique and patented dry electrode formation and manufacturing process with a robust proprietary cell structure design to meet or exceed the most demanding shock and vibration requirements of the growing number of power-hungry applications in global transportation markets.

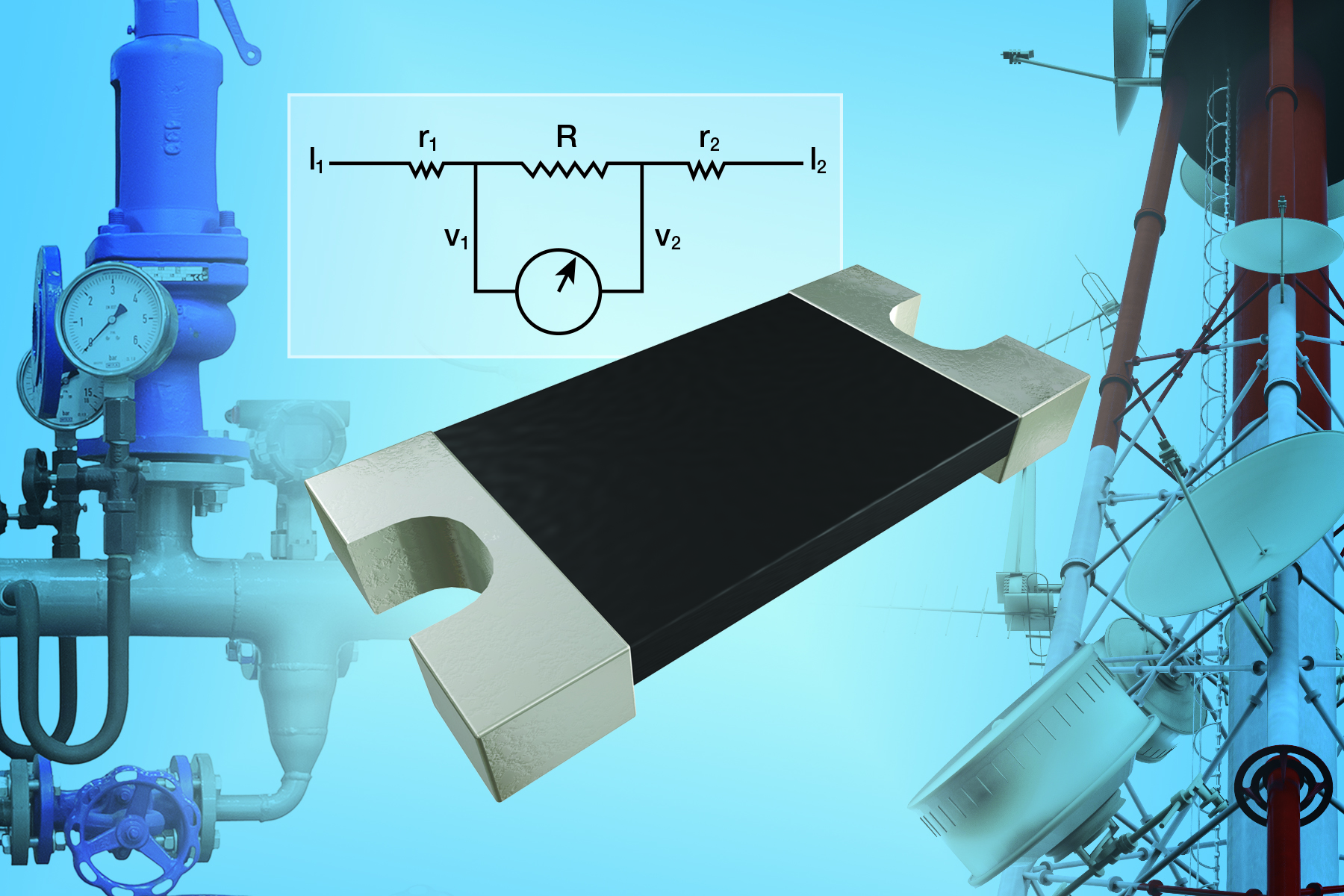

James Hines, research director of Gartner, stated that the high costs and adverse environmental impacts of consuming petroleum-based fuels are driving development of alternative fuels and higher efficiency automotive powertrains. These systems require a source of electrical energy, and batteries have been widely used for energy storage in these applications; however, while batteries can store relatively large amounts of energy over a long period of time, they are limited in their ability to deliver high power to a load. Ultracapacitors are capable of releasing electrical energy at high power levels, and they can accept a high rate of charge, making them an ideal complement to batteries in high-power applications.

Maxwell designs the ultracapacitors by addressing market needs with significant consideration for robustness in construction and reliability in extreme conditions.

The mobility and power industry segments are increasingly integrating Maxwell’s Ultracapacitors taking advantage of their unique characteristics. Ultracapacitors offer more freedom in designing power systems and perform at high technical standards.

Our latest product 2.85V cell successfully extend Maxwell’s product portfolio and enlarge the range of applications to the high shock and vibration environments especially in the automotive, hybrid vehicles, rail, wind turbine pitch control and heavy industrial equipment.

Unlike batteries, Maxwell Ultracapacitor products store energy in an electrical field that is larger than that of a capacitor – meaning ultracapacitors have greater energy storage capacity than capacitors. This electrostatic energy storage mechanism enables ultracapacitors to charge and discharge in as little as fractions of a second, perform normally over a broad temperature range (-40 degrees to +65 degrees C), operate reliably in hundreds of thousands or more duty cycles and resist shock and vibration. Maxwell offers ultracapacitor cells ranging in capacitance from one to 3400 farads and multi-cell modules ranging from 16 to 160 volts, which have proven to deliver high power, whether used alone or paired with batteries, in a variety of applications from automotive or industrial to consumer electronics, transportation and beyond.