Murata develops water repellant monolithic ceramic capacitor to suppress ion migration

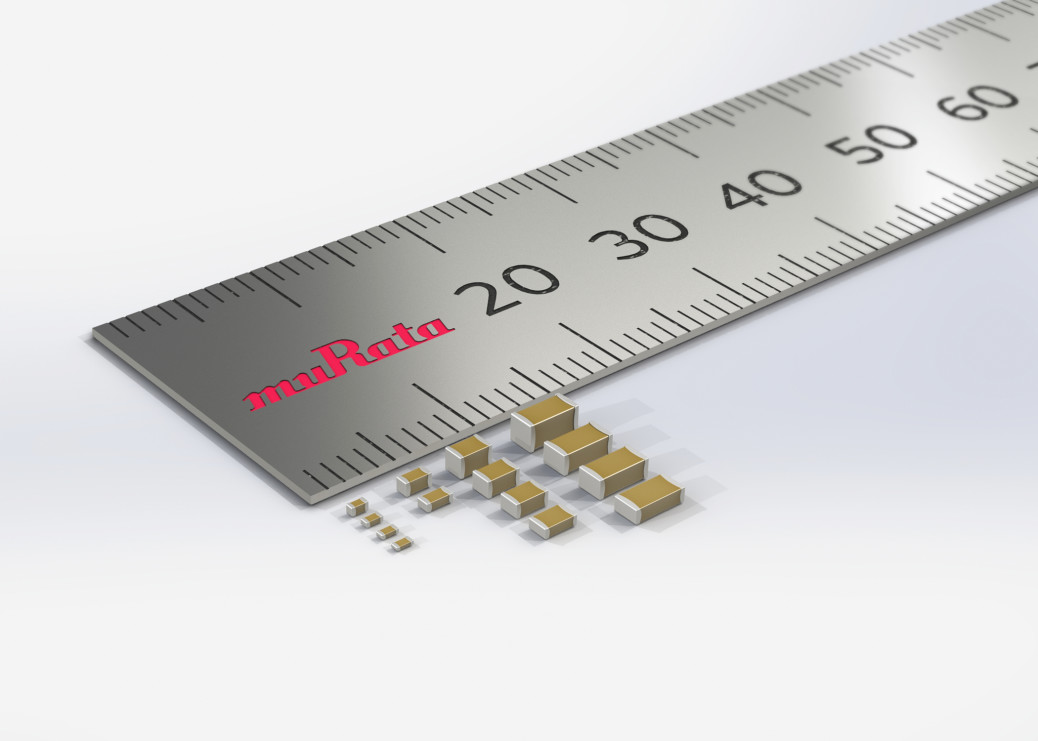

Murata today announced a water-repellent monolithic ceramic capacitor developed by applying an innovative surface Treatment.

Electronic devices are becoming ever more compact and densely packed with components, with this comes an increase in the possibility of malfunctions influencing circuit operation due to ion Migration.

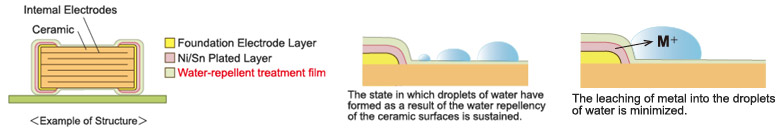

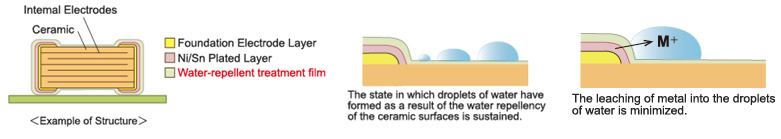

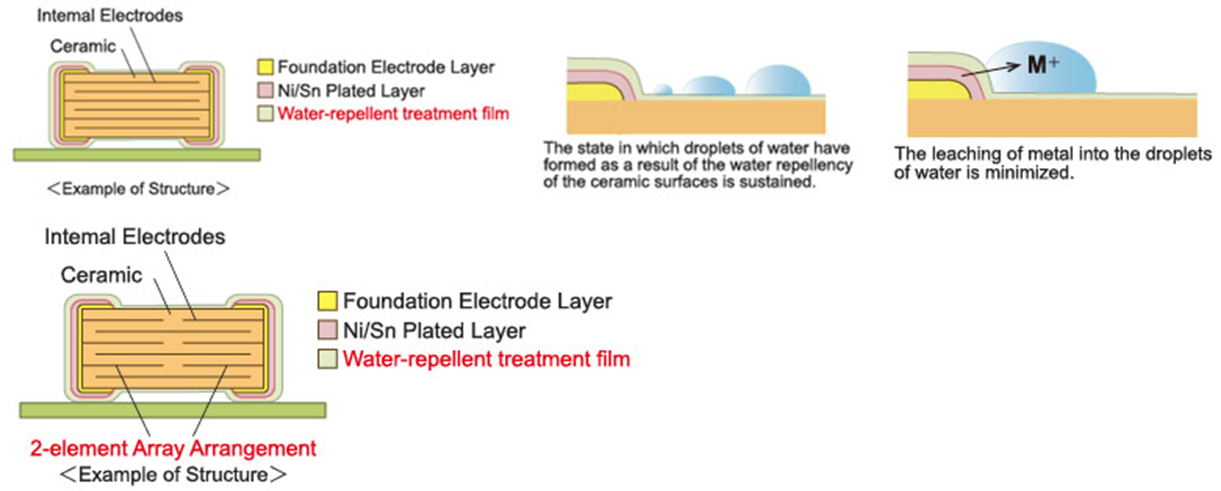

Ion migration may occur when voltage is applied to a capacitor where moisture is present between the electrodes. This may result in the anode metal becoming ionized and changing to a cathode. Then, when gaining electrons as a cathode, the metal may undergo the electrochemical phenomenon of deposition and growth that can eventually result in a short-circuit. This is particularly prone to occur when the capacitor is moistened by condensation.

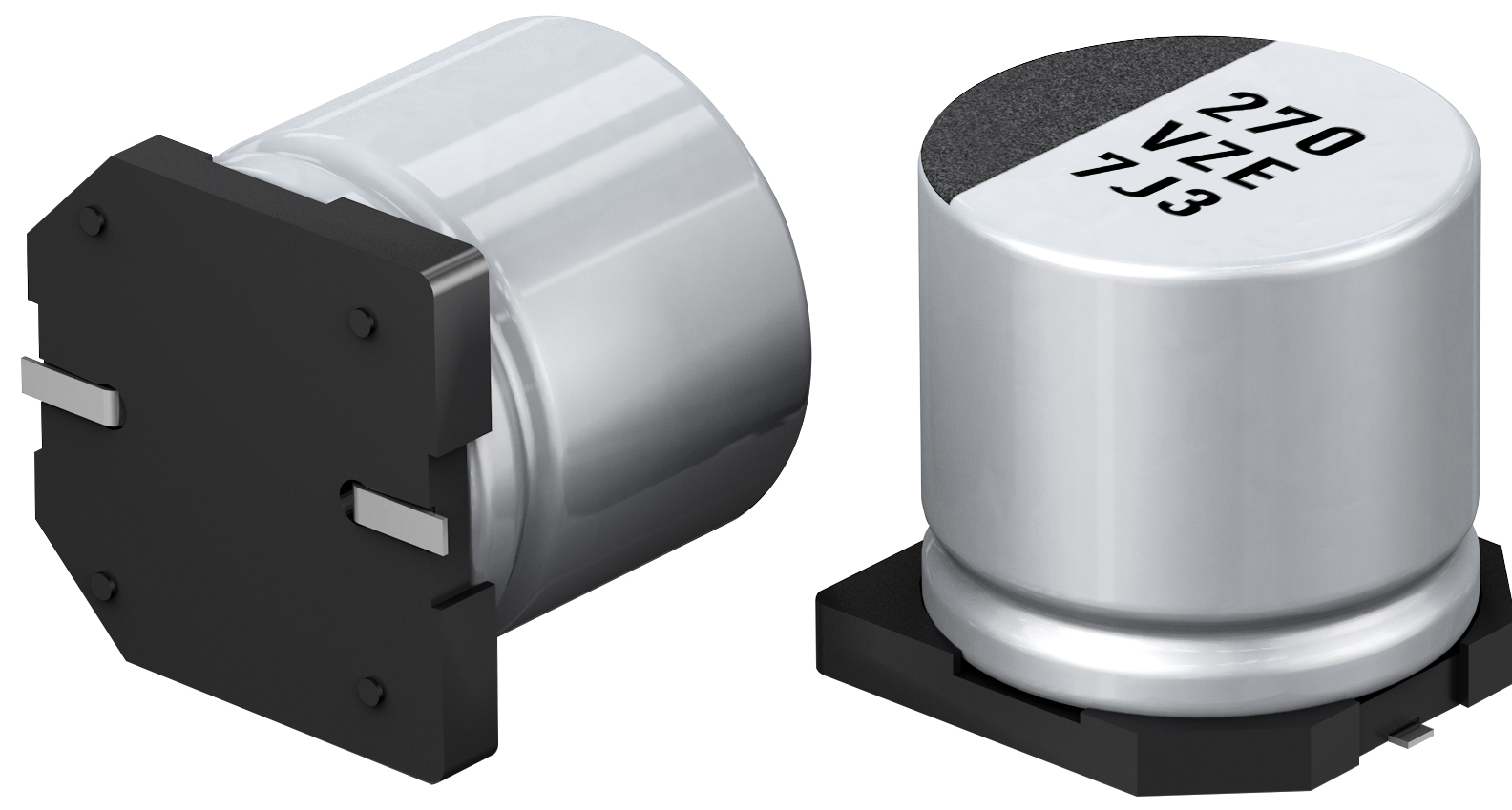

To address this issue Murata has developed a water repellent monolithic ceramic capacitor. The monolithic capacitor is treated with a water-repellant treatment film so that moisture forms into scattered, rather than larger, droplets. These droplets are suppressed to a size that is not big enough to span the gap between the external electrodes and this prevents ion Migration.

This capacitor has applications particularly in navigation systems, body control electronic control units (ECUs), air conditioner ECUs, meter ECUs and engine ECUs, etc.

Sample shipments have already begun and the capacitor is scheduled to enter mass production within the year.

Features GXM, GGM & GGD series

- Minimized Ion migration by water-repellent treatment film to surface

- High reliability with no polarity (GXM series)

- Two-element array structure (GGD series)

-

GXM series – JIS qualified; ideal for consumer & industrial devices

-

GGM series – AEC-Q200*5 qualified; ideal for drive control in ECUs & safety devices

-

GGD series – AEC-Q200 qualified; ideal for automotive battery lines